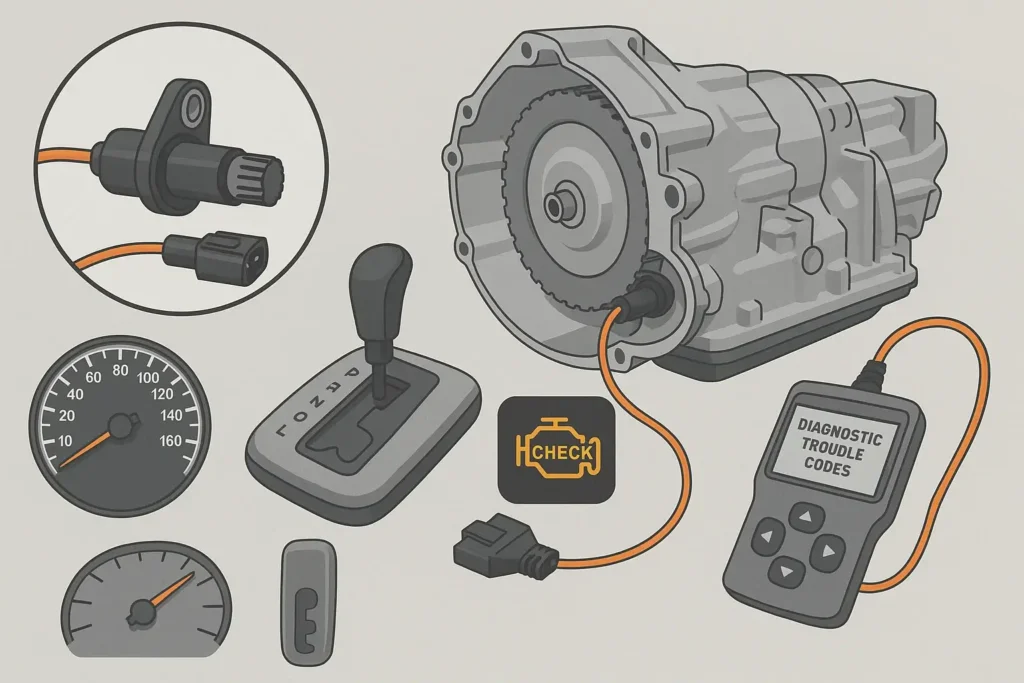

When your car starts shifting erratically, your speedometer behaves oddly, or your check engine light comes on, the problem might be something you’ve never heard of: the transmission speed sensor.

This small but essential component plays a huge role in how your vehicle shifts gears and calculates speed. In this guide, we’ll explain what a transmission speed sensor is, how it works, the symptoms of a bad sensor, and how to diagnose and replace it.

What Is a Transmission Speed Sensor?

A transmission speed sensor (TSS) is a type of vehicle sensor that monitors the rotational speed of either the input shaft or the output shaft of your car’s transmission. The data is sent to your Engine Control Unit (ECU) or Transmission Control Module (TCM) to control functions like:

- Gear shifting

- Torque converter lockup

- Cruise control

- Speedometer readings

Modern vehicles usually have two speed sensors:

- Input Speed Sensor (ISS): Measures the speed of the transmission input shaft.

- Output Speed Sensor (OSS): Measures the speed of the output shaft or driveshaft.

These sensors help your transmission know when and how to shift gears smoothly and efficiently.

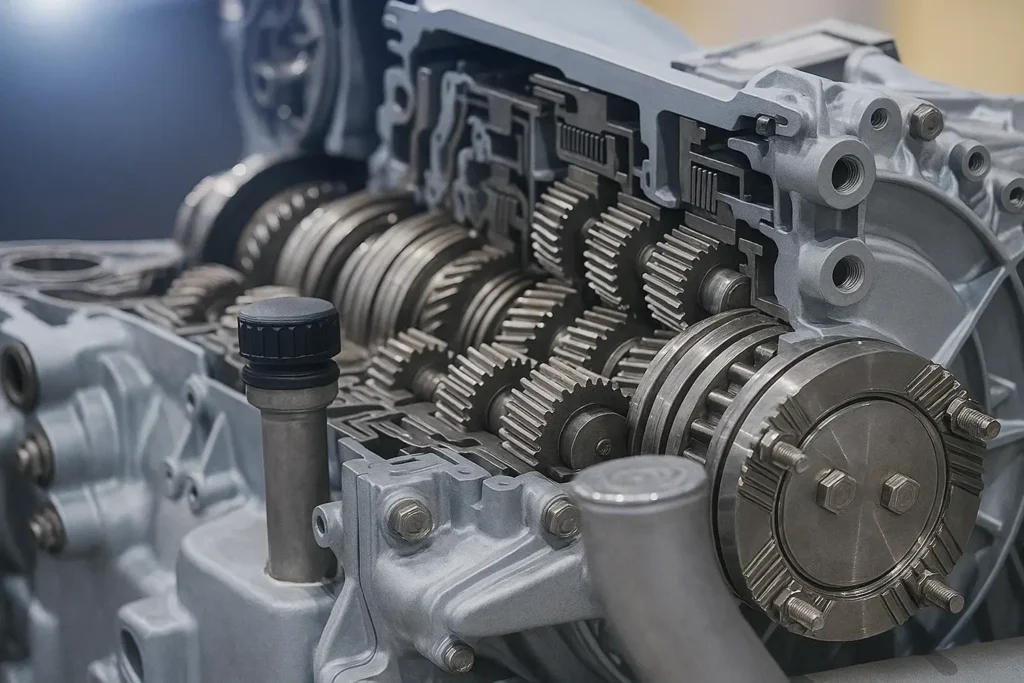

How the Transmission Speed Sensor Works

Speed sensors are usually magnetic or Hall-effect sensors that generate an electrical signal based on the rotational speed of a shaft inside the transmission.

The sensor sends this information to the ECU/TCM, which uses it to:

- Determine real-time vehicle speed

- Manage gear shifting

- Monitor transmission performance

- Trigger warning lights or diagnostic trouble codes (DTCs)

In automatic vehicles, incorrect data from the speed sensor can result in harsh shifting or failure to shift altogether.

Symptoms of a Bad Transmission Speed Sensor

When a transmission speed sensor fails, the vehicle’s performance and drivability are often affected. Here are the most common signs of a faulty speed sensor:

1. Erratic or Harsh Shifting

- The car may shift too early or too late.

- You might experience hard, jerky transitions between gears.

2. Speedometer Malfunctions

- Your speedometer may bounce, drop to zero, or stop working altogether.

3. Check Engine Light or Transmission Warning Light

- The vehicle’s ECU detects incorrect speed signals and triggers a warning.

4. Transmission Stuck in One Gear (Limp Mode)

- Some vehicles go into “limp mode” to protect the transmission, restricting speed and gear usage.

5. Poor Fuel Efficiency

- Improper shifting can lead to engine strain and reduced fuel economy.

Common Trouble Codes

A bad speed sensor can trigger OBD-II codes like:

- P0720: Output speed sensor circuit malfunction

- P0715: Input speed sensor malfunction

- P0722: No signal from output speed sensor

Tip: A basic OBD-II scanner can help you retrieve these codes.

Diagnosing a Faulty Transmission Speed Sensor

1. Visual Inspection

- Check for signs of physical damage, corrosion, or fluid contamination on the sensor or its connector.

- Inspect wiring for fraying, disconnection, or exposed areas.

2. Scan for Trouble Codes

- Use an OBD-II scanner to identify speed sensor-related codes.

- Note which sensor (input or output) is indicated.

3. Test the Sensor with a Multimeter

If you’re comfortable with DIY diagnostics:

- Disconnect the sensor.

- Set your multimeter to measure resistance or AC voltage.

- Spin the wheel or shaft (if accessible) and look for a changing voltage or resistance.

Compare your readings with the manufacturer’s specifications. If the reading is off, the sensor is likely bad.

How to Replace a Transmission Speed Sensor (Step-by-Step)

Replacing a transmission speed sensor is usually a straightforward task for mechanically inclined DIYers.

Tools and Materials Needed

- Replacement speed sensor (OEM or high-quality aftermarket)

- Socket set and ratchet

- Torque wrench

- Screwdriver or pry tool

- Jack and jack stands (if access requires lifting the vehicle)

- Dielectric grease (optional)

General Replacement Process

- Disconnect the battery for safety.

- Locate the sensor—refer to your service manual. It’s typically near the transmission tailshaft or bell housing.

- Disconnect the electrical connector.

- Remove the mounting bolt with a socket wrench.

- Gently remove the old sensor.

- Install the new sensor, apply dielectric grease to the connector if desired.

- Reinstall the mounting bolt and torque to manufacturer specs.

- Reconnect the electrical connector.

- Reconnect the battery, clear error codes using a scanner, and test drive.

⚠️ Note: The process may vary depending on your make and model.

Transmission Speed Sensor Replacement Cost

Here’s a general breakdown of what you can expect:

| Type of Cost | Price Range |

|---|---|

| DIY Parts Only | $20 – $100 |

| Professional Labor | $80 – $200 |

| Total (Shop Repair) | $100 – $300+ |

Factors affecting cost include:

- Vehicle make and model

- Labor rates in your area

- Whether one or both sensors need replacing

Can You Drive With a Bad Transmission Speed Sensor?

Technically, yes for a short distance, but it’s not recommended.

A failing sensor affects how your car shifts and reads speed, which can:

- Trigger limp mode, restricting acceleration

- Cause erratic or unsafe shifting

- Lead to engine strain or fuel inefficiency

- Result in further transmission damage if ignored

If you suspect a bad speed sensor, it’s best to address it immediately.

Preventing Speed Sensor Issues

While not entirely preventable, you can reduce your risk of speed sensor failure with a few good habits:

- Keep transmission fluid clean and topped off

- Repair fluid leaks quickly—leaks can short out sensors

- Avoid deep water or off-road conditions that expose sensors

- Schedule regular diagnostic scans if you notice performance changes

- Include sensor checks during transmission service intervals

Conclusion

The transmission speed sensor may be small, but it plays a massive role in how your vehicle shifts, drives, and performs. From detecting vehicle speed to controlling gear changes, a bad sensor can lead to frustrating—and expensive—issues if ignored.

By recognizing the symptoms, using diagnostic tools, and either replacing the sensor yourself or seeking professional help, you can prevent transmission damage and restore your vehicle’s performance.

FAQs

How to test a transmission speed sensor?

To test a transmission speed sensor, you typically need a multimeter and basic knowledge of your vehicle’s wiring. First, locate the sensor (usually mounted on the transmission housing), disconnect it, and inspect the wiring for damage. Set your multimeter to measure resistance (ohms), then check the sensor’s terminals. A healthy sensor will show a specific resistance range (consult your vehicle manual for specs). You can also perform a voltage test while the car is running to ensure the sensor outputs a signal when the transmission is in motion.

Can a wheel speed sensor affect the transmission?

Yes, a wheel speed sensor can affect the transmission, especially in vehicles equipped with ABS and traction control systems. These sensors help the ECU determine how the transmission should behave under different road conditions. If a wheel speed sensor sends faulty data, it can confuse the transmission control module, resulting in hard shifting, incorrect gear selection, or triggering limp mode. It's essential to diagnose both wheel and transmission sensors when transmission issues occur.

How to test a transmission speed sensor with a multimeter

To test a transmission speed sensor with a multimeter:

Turn off the engine and locate the speed sensor on the transmission.

Disconnect the wiring harness from the sensor.

Set your multimeter to Ohms (Ω) to measure resistance.

Place the probes on the sensor terminals. A functioning sensor should show a consistent resistance value, typically between 200 and 2000 ohms (refer to your vehicle’s service manual).

If available, test for AC voltage output by spinning the transmission shaft manually while the multimeter is set to AC volts. You should see fluctuating voltage as the shaft spins.

If the readings are out of range or you get no response, the sensor may be faulty and require replacement.

What does a transmission speed sensor do?

A transmission speed sensor monitors the rotational speed of your vehicle’s transmission shafts and sends this data to the engine or transmission control unit. This information is critical for determining shift timing, torque converter lockup, and proper engine load management. Most vehicles use two sensors: an input speed sensor (measures speed from the engine) and an output speed sensor (measures speed to the wheels). Together, they ensure smooth shifting, optimal fuel efficiency, and overall transmission health.