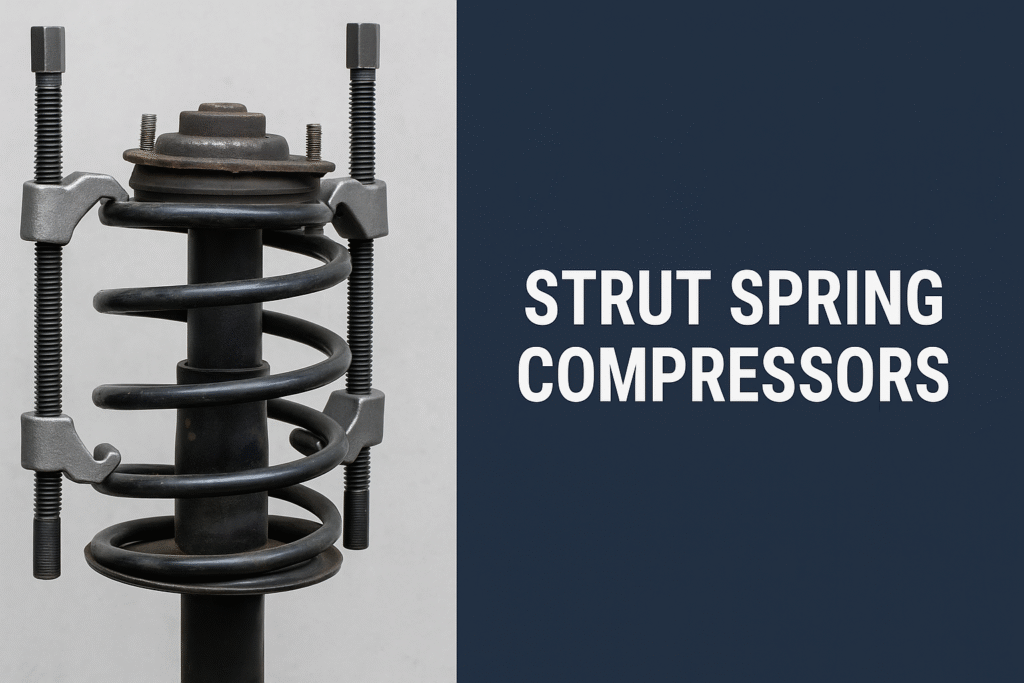

When it comes to working on your vehicle’s suspension system, one tool stands out for its importance: the strut spring compressor. Whether you’re a professional mechanic or a DIY enthusiast, having the right tools for suspension repairs is essential. A strut spring compressor allows you to safely remove and install strut springs, which can be dangerous without the proper equipment. In this comprehensive guide, we’ll cover everything you need to know about strut spring compressors—from their types and uses to safety tips and maintenance.

What is a Strut Spring Compressor?

A strut spring compressor is a specialized tool used to compress the coil springs in a vehicle’s suspension system. These springs are crucial for maintaining the vehicle’s ride quality by absorbing shocks from the road. Strut springs, however, are under significant tension and can be dangerous if handled improperly. The compressor helps safely release or apply this tension, making it easier to remove or install struts during repair work.

Why You Need a Strut Spring Compressor for Suspension Repairs

Strut spring compressors are essential when performing repairs or maintenance on strut assemblies. Whether you need to replace worn-out springs, replace struts, or perform suspension upgrades, a compressor ensures that the springs are safely compressed, preventing them from releasing suddenly, which could cause injury or damage. Without a strut spring compressor, handling these springs can be hazardous and lead to costly mistakes.

Types of Strut Spring Compressors

There are several types of strut spring compressors, each with its benefits and drawbacks. Choosing the right one for your needs depends on your vehicle, the type of suspension, and your preferred level of effort when using the tool.

Manual Strut Spring Compressors

Manual strut spring compressors are the most basic and economical option. They typically consist of two hooks that attach to the spring and a central screw or bolt that tightens them. The user turns the screw to compress the spring.

Pros and Cons of Manual Compressors

- Pros:

- Affordable and easy to use.

- Lightweight and portable.

- Ideal for occasional use by DIY enthusiasts.

- Affordable and easy to use.

- Cons:

- Requires physical effort to operate.

- May not provide enough force for large or heavy springs.

- Can take more time to compress the spring fully.

- Requires physical effort to operate.

Hydraulic Strut Spring Compressors

Hydraulic compressors use fluid power to compress the spring. These tools are more efficient than manual compressors, requiring less physical effort from the user. Hydraulic compressors are often used in professional shops and are ideal for heavy-duty applications.

Pros and Cons of Hydraulic Compressors

- Pros:

- Faster and less effort-intensive.

- Suitable for heavy-duty springs and frequent use.

- More precise control over compression.

- Faster and less effort-intensive.

- Cons:

- Generally more expensive than manual compressors.

- Larger and bulkier, requiring more storage space.

- Can be overkill for casual or one-time users.

- Generally more expensive than manual compressors.

Pneumatic Strut Spring Compressors

Pneumatic strut spring compressors use air pressure to provide even more power and efficiency. These tools are used primarily by professional mechanics who need to perform many spring compressions quickly.

Pros and Cons of Pneumatic Compressors

- Pros:

- Very fast and powerful.

- Great for high-volume work and commercial use.

- Offers consistent, even compression with minimal effort.

- Very fast and powerful.

- Cons:

- Requires an air compressor, adding to the cost.

- Higher cost compared to hydraulic or manual options.

- Not necessary for casual DIY users or small-scale jobs.

- Requires an air compressor, adding to the cost.

Electric Strut Spring Compressors

Electric compressors use an electric motor to apply force, making them a more automated and convenient option. These tools are suitable for those who want a balance between ease of use and power.

Pros and Cons of Electric Compressors

- Pros:

- Easy to use with minimal manual effort.

- Faster than manual compressors.

- More consistent results compared to manual methods.

- Easy to use with minimal manual effort.

- Cons:

- Higher initial cost compared to manual and hydraulic compressors.

- Requires an electrical power source, which may not be ideal for every workspace.

- Heavier and bulkier than manual options.

- Higher initial cost compared to manual and hydraulic compressors.

Key Features to Look for in a Strut Spring Compressor

When selecting a strut spring compressor, consider the following key features to ensure you’re getting the right tool for your needs.

Weight and Capacity

It’s essential to choose a strut spring compressor that matches the weight and size of the springs you’re working with. The capacity of the compressor determines how much force it can exert. For larger vehicles with heavier springs, you’ll need a compressor with a higher weight capacity.

Adjustability and Versatility

Look for a compressor that offers adjustability in terms of arm size and gripping force. Adjustable arms allow you to work with various spring sizes and types. This feature is especially important if you work on different vehicles with varying suspension systems.

Build Material and Durability

Strut spring compressors are subjected to significant stress and force. Look for models made from high-quality materials like forged steel or aluminum. These materials ensure durability and long-lasting performance.

Safety Features

Strut spring compressors can be dangerous if not used properly. Some models come equipped with safety features like locking pins, anti-slip grips, and spring catchers to prevent the spring from snapping back unexpectedly.

How to Use a Strut Spring Compressor Safely

Using a strut spring compressor requires careful attention to safety and proper technique. Here’s a step-by-step guide on how to use the tool effectively.

Step-by-Step Guide to Using a Strut Spring Compressor

- Prepare the Vehicle: Make sure the vehicle is securely lifted, and the suspension is fully unloaded.

- Attach the Compressor: Place the compressor on the spring, ensuring the hooks or arms grip it securely.

- Begin Compressing the Spring: Slowly turn the compressor’s handle or screw to compress the spring evenly. Always apply gradual, steady force.

- Check for Stability: Ensure the compressor remains stable and that the spring is compressed symmetrically.

- Remove the Spring: Once the spring is fully compressed, carefully remove the strut assembly from the vehicle, and slowly release the spring tension once it is safely out.

Essential Safety Tips When Using Strut Spring Compressors

- Always wear protective gear: Wear gloves, safety glasses, and steel-toed boots to protect yourself from any flying debris or accidents.

- Use the correct tool for the job: Ensure your compressor is rated for the weight and size of the spring you’re working on.

- Never rush: Compressing strut springs requires patience. Take your time to ensure everything is aligned properly and that you’re using the tool safely.

- Avoid sudden releases: Never attempt to release the spring quickly or forcefully, as this could cause the spring to snap, posing a significant danger.

Maintenance and Care for Strut Spring Compressors

How to Maintain Your Strut Spring Compressor for Longevity

Regular maintenance of your strut spring compressor ensures that it continues to function safely and effectively. Here are a few maintenance tasks:

- Clean regularly: After use, wipe down the compressor to remove any dirt or grease that may have built up.

- Lubricate moving parts: For hydraulic or electric compressors, keep the moving parts lubricated to prevent rust and ensure smooth operation.

- Inspect for wear and tear: Regularly check the tool for cracks, corrosion, or loose components. Replace any damaged parts immediately.

Storing Your Strut Spring Compressor Properly

To ensure the longevity of your tool, store it in a dry, cool place. Keep the compressor off the ground and out of direct sunlight to prevent rust or degradation.

When to Replace Your Strut Spring Compressor

If you notice any signs of significant damage or the compressor is no longer able to compress springs effectively, it’s time to replace it. Always prioritize safety—don’t use a tool that is damaged or malfunctioning.

Buying a Strut Spring Compressor: Factors to Consider

Price Range of Strut Spring Compressors

Strut spring compressors vary in price based on their type, brand, and features. Manual compressors typically cost between $30 and $100, while hydraulic and pneumatic models can range from $100 to $500 or more.

Top Strut Spring Compressor Brands and Reviews

Some reputable brands that consistently produce high-quality strut spring compressors include:

- OTC Tools

- Lisle

- GearWrench

- Torin

Before purchasing, check online reviews to ensure the product meets your needs.

Where to Buy Strut Spring Compressors

Strut spring compressors are available from a variety of retailers, including:

- Amazon: Offers a wide range of models with customer reviews for better insight.

- Auto parts stores: Physical stores like AutoZone or Advance Auto Parts typically carry reputable brands.

- Specialty tool suppliers: Stores dedicated to automotive tools, like Harbor Freight or Grainger, offer a range of options.

Conclusion

Whether you’re replacing strut springs on your personal vehicle or working in a professional shop, a strut spring compressor is an essential tool for the job. By understanding the different types, features, and safety measures, you can ensure you’re choosing the right compressor for your needs. With proper maintenance and safe handling, a strut spring compressor will help you perform suspension repairs with ease and efficiency.

Frequently Asked Questions (FAQ)

How Do I Know If My Strut Spring Compressor Is Properly Sized?

Check the tool's specifications to ensure it’s rated for your vehicle’s suspension springs. A compressor that's too small may not provide enough force, while a tool that’s too large can be difficult to use.

Are Strut Spring Compressors Safe to Use?

Strut spring compressors are safe to use when the proper precautions are taken. Always follow the manufacturer’s instructions, wear protective gear, and use the tool on stable, secure surfaces.